Metal Roof Recall: Essential Insights on Defective Fasteners

Property owners select metal roofs for their exceptional durability, extended lifespan, and minimal upkeep requirements. However, recent reports of a nationwide recall on certain fasteners introduce uncertainty. These components secure the roof panels, and any failure compromises the overall structure against weather elements and daily stresses.

This resource outlines the recall details, associated hazards, and concrete actions to safeguard your property. Readers gain knowledge on detecting impacted products, engaging professionals, and implementing preventive measures to uphold roof integrity.

2. Assessing If Your Roof Involves Recalled Fasteners

Begin evaluation by reviewing installation invoices, product specifications, and warranty documents for details on fastener brands, models, and suppliers. Focus on identifiers such as batch codes or manufacturing dates printed on the components. For standing seam roofs, examine washer markings; for exposed fastener systems, inspect screw shank engravings.

In the absence of records, consult the original roofing contractor or contact the panel manufacturer with your roof's age, type, and location details. Professionals access databases to verify inclusion in the recall. Professional verification avoids assumptions that could overlook hidden risks and subsequent repair expenses.

4. Thorough Documentation of Inspection Findings

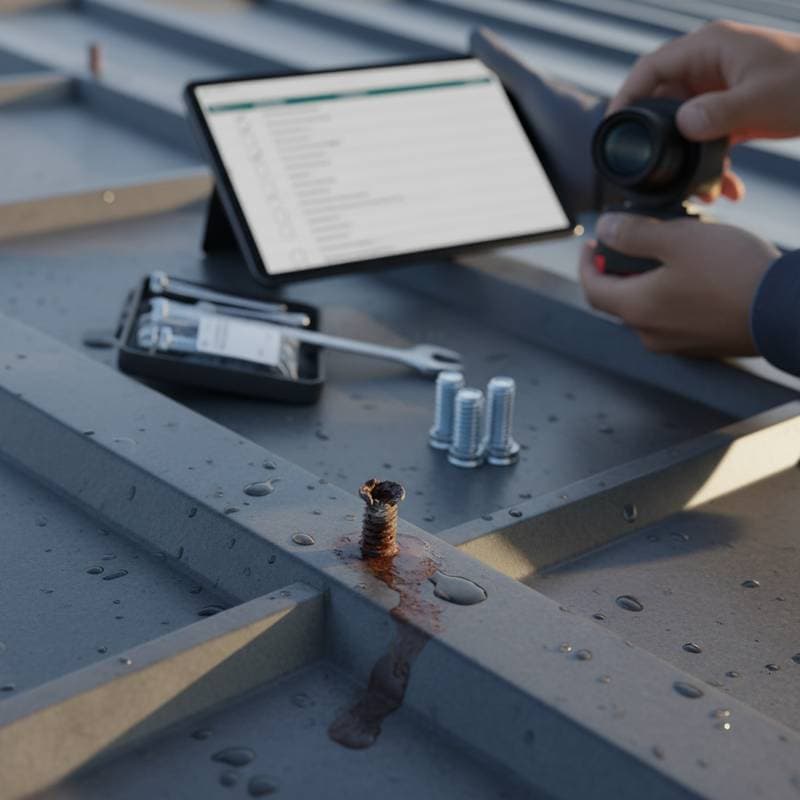

Upon discovering anomalies, capture high-resolution images from multiple angles, including close-ups of corroded heads, stripped threads, or sealant failures. Note environmental factors like proximity to coastal areas that accelerate degradation. Compile a digital folder with timestamps, alongside inspector certifications and narrative descriptions.

Organized records facilitate warranty activations, recall claims, or legal recourse if disputes arise. Manufacturers require evidence of defect correlation to approve remedies. Systematic documentation streamlines interactions and maximizes recovery of associated costs.

6. Executing Timely Replacement of Faulty Fasteners

Post-verification, prioritize swaps to mitigate progression of damage like wind-driven panel shifts. Engage licensed contractors experienced in metal roofing, who utilize torque wrenches for precise installation matching original specifications. Replacements incorporate self-sealing washers to restore waterproofing integrity.

Specify compatibility: pair aluminum panels with coated steel screws to prevent electrolytic reactions. Professionals apply anti-seize compounds on threads for future removals. Complete replacements restore load-bearing capacity and extend service life by decades.

7. Uncovering and Remedying Concealed Damage

Fastener breaches permit insidious water penetration behind panels, saturating insulation and sheathing. Inspectors probe for dampness using moisture meters, targeting seams and valleys where pooling occurs. Rot in wooden purlins or mold in attics demands immediate extraction and antimicrobial treatments.

Contractors install vapor barriers and reapply panel adhesives during repairs. Address ventilation deficiencies to expel humidity. Proactive remediation halts decay cycles, preserving insulation efficiency and indoor air quality.

8. Establishing Ongoing Maintenance Protocols

Post-repair, integrate annual visual audits into property care routines, focusing on fastener tightness via spot torque checks. Post-storm evaluations assess debris impacts and wind effects, tightening any loosened elements promptly. Clear debris from valleys and ensure proper flashing alignment to divert runoff.

Document maintenance logs with dates and observations to validate warranty terms, often requiring biennial professional verifications. These practices sustain performance, averting minor issues from compounding into major failures.

9. Monitoring Industry Developments for Informed Choices

Recalls catalyze advancements, such as mandatory third-party certifications for fastener durability. Subscribe to associations like the Metal Roofing Alliance for alerts on standards updates and emerging technologies like UV-resistant coatings.

For future projects, request material safety data sheets and proof of compliance from suppliers. Select installers with certifications in metal systems. Informed selections minimize exposure to defects and enhance long-term reliability.

Securing Your Roof's Future Through Vigilance

Addressing fastener concerns transforms potential vulnerabilities into fortified assets. Owners who act decisively protect investments, comply with safety mandates, and enjoy uninterrupted shelter. Regular diligence ensures metal roofs deliver on promises of resilience for generations.